FUZE – Leading the Charge in Reliable Energy Storage

Kerala, known for its lush greenery, backwaters, and progressive approach to technology, is also home to a growing demand for uninterrupted power solutions. With frequent power outages and an increasing reliance on energy-efficient systems, the need for high-quality batteries is more critical than ever. One name that stands out in the industry is FUZE, a trusted tubular battery manufacturer in Kerala that is revolutionizing the way homes and businesses store power.

The Growing Demand for Tubular Batteries in Kerala

Power fluctuations and unpredictable outages have made it necessary for households and businesses to invest in durable and efficient backup power solutions. While traditional flat plate batteries serve their purpose, tubular batteries have gained popularity due to their longer lifespan, high efficiency, and superior deep-cycle performance. They are especially preferred in regions like Kerala, where the humidity and temperature variations demand robust energy storage solutions.

FUZE understands these challenges and has tailored its range of tubular batteries to withstand Kerala’s climate, ensuring optimal performance even in extreme weather conditions.

Why FUZE Tubular Batteries?

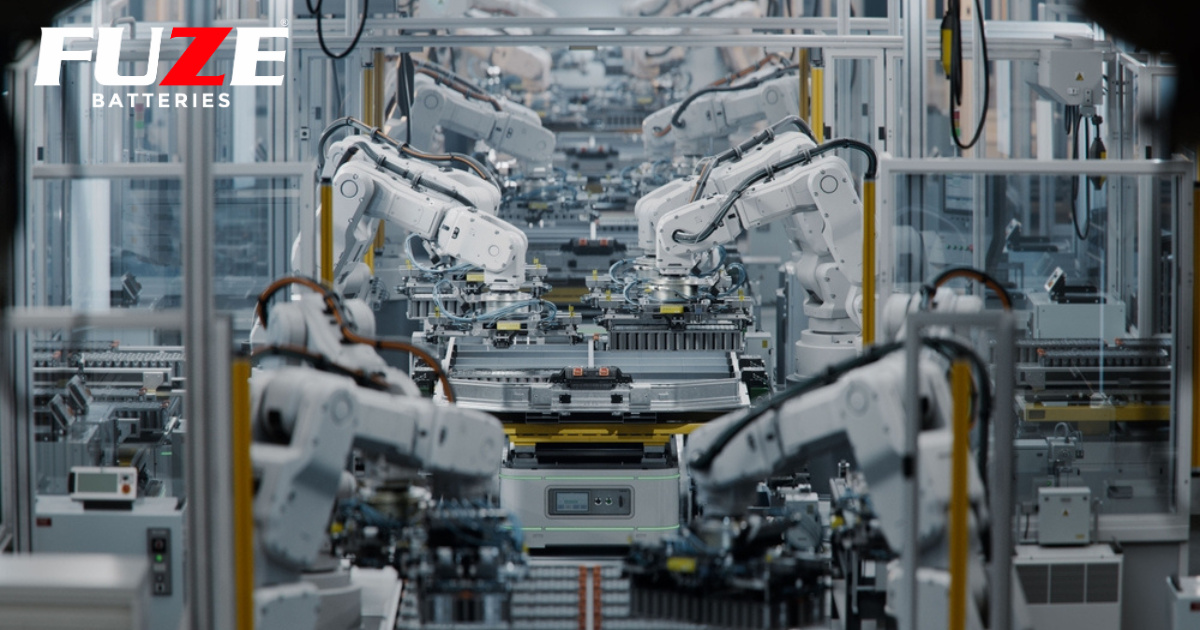

As a leading tubular battery manufacturer in Kerala, FUZE has carved a niche in the market with its cutting-edge technology, superior build quality, and commitment to sustainability. Here’s why FUZE batteries are the top choice for residential, commercial, and industrial users:

1. Superior Performance & Longevity

FUZE tubular batteries are designed with high-performance lead-acid technology that ensures longer life cycles compared to conventional batteries. Their deep discharge recovery capability makes them ideal for frequent power cuts, providing reliable backup for homes and businesses.

2. High Energy Efficiency

The unique tubular design allows for better electrolyte retention and minimal water loss, ensuring low maintenance and high efficiency. This makes FUZE batteries a cost-effective solution in the long run.

3. Resistant to Harsh Conditions

Kerala’s tropical climate demands batteries that can withstand high temperatures and humidity. FUZE tubular batteries are built with corrosion-resistant materials, ensuring durability and consistent performance in extreme weather conditions.

4. Eco-Friendly & Sustainable

FUZE is committed to green energy solutions by manufacturing eco-friendly batteries with recyclable components. The company follows strict environmental guidelines to minimize its carbon footprint, aligning with Kerala’s vision of a sustainable future.

5. Ideal for Solar Applications

With Kerala witnessing a surge in solar energy adoption, FUZE tubular batteries serve as the perfect energy storage solution. They are compatible with solar power systems, providing uninterrupted backup even during prolonged power failures.

FUZE – Powering Homes & Businesses Across Kerala

FUZE batteries are widely used across multiple sectors in Kerala:

Residential: Ensuring an uninterrupted power supply for homes, making life convenient even during extended outages.

Commercial Establishments: From offices to retail stores, FUZE batteries provide seamless backup to keep businesses running.

Industrial & Agricultural Use: Industries and farms rely on FUZE batteries for efficient and sustainable energy storage solutions.

Solar & Renewable Energy: A preferred choice for solar battery storage, making it ideal for eco-conscious users.

Choose FUZE – Your Reliable Energy Partner

If you are looking for a trusted tubular battery manufacturer in Kerala, FUZE is your go-to brand. With an unwavering commitment to quality, innovation, and customer satisfaction, FUZE continues to empower homes and businesses with cutting-edge energy solutions.

Whether you need a durable home inverter battery or a high-capacity industrial power backup solution, FUZE has the perfect battery to meet your needs. Invest in FUZE tubular batteries today and experience unmatched performance, reliability, and efficiency!For more information, visit FUZE’s official website or reach out to their authorized dealers across Kerala.